The Premier Aluminum Llc Ideas

Rumored Buzz on Premier Aluminum Llc

Table of ContentsThe smart Trick of Premier Aluminum Llc That Nobody is DiscussingPremier Aluminum Llc Fundamentals ExplainedNot known Facts About Premier Aluminum LlcAll about Premier Aluminum LlcPremier Aluminum Llc - Truths

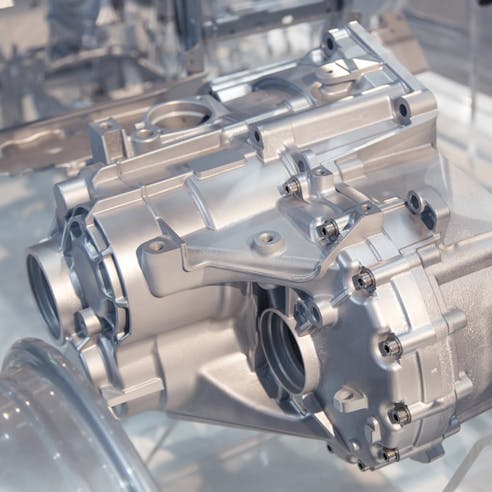

When picking a light weight aluminum factory for your manufacturing demands, it's crucial to study a number of aspects. Among the most vital aspects to take into consideration is the experience and capability of the foundry. Picking a factory that has the right expertise of the light weight aluminum casting procedure, and the portfolio to show for it, helps to have a successful result for your job.Having the experience and sector knowledge to craft your castings for ideal production and high quality outcomes will streamline the task. Producing light weight aluminum spreading needs a complex set of procedures to accomplish the ideal outcomes. When selecting a new aluminum foundry to companion with, guarantee they have extensive industry experience and are educated concerning all aspects of the aluminum spreading procedure: style, manufacturing, product evaluation, and item screening.

The foundry needs to likewise have a tested record of providing extraordinary products that fulfill or surpass customer assumptions. Quality assurance ought to likewise go to the top of your list when selecting a light weight aluminum shop. By functioning with a qualified foundry that complies with the standards for quality assurance, you can protect the integrity of your product and guarantee it meets your requirements.

8 Easy Facts About Premier Aluminum Llc Described

This certain process can be automated and duplicated. Different elements that very complicated forms can be manufactured using this process. Consequently, big volumes of components can be produced in just a short amount of time. Before you begin looking for a trusted light weight aluminum die caster, there are some vital points that you need to do first.

You have to ask on your own what kind of aluminum pass away spreadings you need. After determining what you need, you have to mention the specifications of the light weight aluminum pass away spreadings you need.

After having this info, you can start investigating aluminum die-casting producers. You can do this by just typing the keyword phrase" Aluminum die casting manufacturers" on the Google search engine.

A few of the questions you need to ask yourself are whether they have actually experienced and trained drivers, for how long their service has functioned, or if they have some accomplishments. You can commonly get the response to these inquiries from the producer's website. You can research various other web sites or outside sources to validate if the info given on the maker's internet site find here is authentic.

An Unbiased View of Premier Aluminum Llc

One more point you need to take into consideration is the producer's capacity to create aluminum die-casting items. In other words, the quantity of items the manufacturer can create at a provided time. A few of the crucial questions you need to ask yourself are whether the maker can generate a greater volume or can the manufacturer fulfill your needs.

(https://penzu.com/p/c7a1eb9a399a9a03)What happens if your business needs 10,000 pieces of particular machine parts from the maker within one month? You got this quantity; however, the supplier can just produce 5000 pieces of these machine components within one month (Aluminum Metal casting). As an outcome, you won't be able to obtain the quantity that you buy in a timely manner

Some Ideas on Premier Aluminum Llc You Need To Know

Hence, it is essential that you need to make inquiries if the supplier is implementing an internal tooling procedure. Additionally, you have to ask the manufacturer just how much the cost of internal tooling is. Remember that the internal tooling process, which allows you to create distinctive styles and shapes can be an added cost.

This element directly correlates with the maker's production ability. Foundry near me. You have to look for a producer that can make certain quicker shipment of products.

This implies that there are a number of options that you can pick from. Today, customer demands maintain on transforming. It seems that clients are looking for an excellent combination of high quality, cost-effectiveness, and toughness. That is why it is substantially advised that you ought to choose a maker that can create various kinds of aluminum die-cast products.

A Biased View of Premier Aluminum Llc

The majority of frequently, these light weight aluminum die-casting items will certainly require some decors, machining, or finishing touches. Having this in mind, you need to seek a supplier that can carry out a variety of secondary ending up jobs when die casting is done. Some examples of ending up procedures include Chromating, CNC Machining, Sandblasting, Powder finish, Anodized, E-coating, Wet paint, Plating, and several more.

Die casting is one of the most economical, accurate, and protean manufacturing procedures in the world moment. The procedure involves suitable molten essence, under pressure, into a suitable die (planet), and formerly strengthened it can be ejected and ended up (if needed) in a variety of methods.